- Proven ultrasonic transit time measurement

- Single or multi path measurement up to 32 measurement paths with extension modules

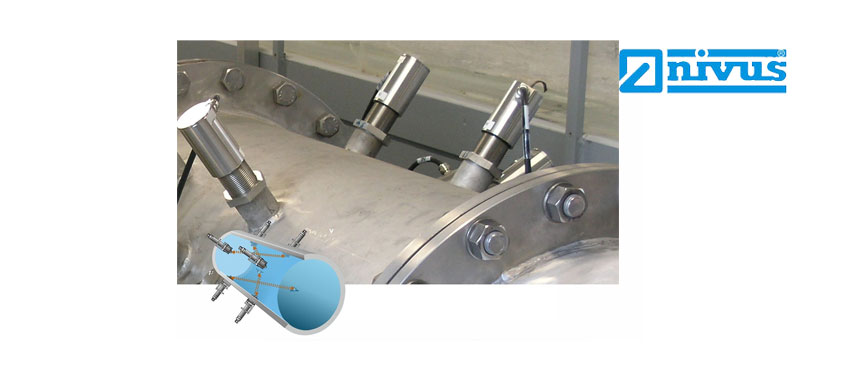

- Insert or clamp-on-sensors available

- Easy installation without interruption of running processes

- Easy setup due to guided sensor positioning

- Intuitive, modern operating concept for quick and easy initial start-up

- IP68 weatherproof version for outdoor use available

- IoT-ready with global 4G connectivity for highest availability and digital services

- Energy-saving cycle operation for self-sufficient systems

Perfect flow measurement in full pipelines Insert or clamp-on

The NivuFlow 600 system was developed particularly for flow measurement in full pipes. To meet the highest possible accuracy requirements it is possible to utilise up to 32 velocity paths. There are pipe sensors as well as contactless clamp-on sensors available for the measurement system. It is not necessary to interrupt running processes to install both sensor types. The system is suitable for the detection of flow rates in various liquid media covering a wide range of applications.

Flow measurement systems at the highest technical level

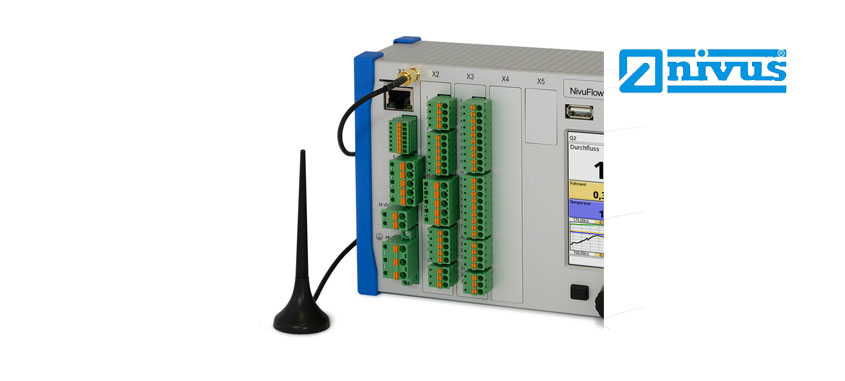

The compact enclosure can be easily integrated into switching cabinets saving space thanks to DIN rail mounting. Moreover, the NivuFlow 600 units are available in a special field enclosure for use in rough environmental conditions.

The transmitter‘s large graphic display allows quick and easy commissioning of the flow metering system. It further-more provides extended diagnostic options and enables in-depth analyses of running processes on site.

The transmitter software was newly developed from scratch. Using future-proof protocols and versatile options for communication and connections opens a wide variety of options to operators when it comes to integrate the instruments into higher systems such as SCADA or process conducting systems.

Typical applications

- Hydropower

- Leakage monitoring

- Irrigation systems (volume distribution and billing)

- Inlets and outlets conducting cooling water or circulation systems

- Industry: process water, slightly polluted water and more

- Comparative measurements

- Pump monitoring and verification

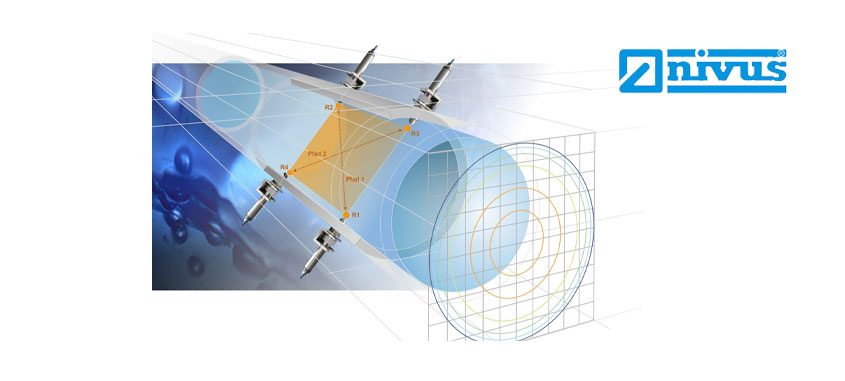

The measurement principle

The NivuFlow 600 measurement principle is based on detecting the transit time of ultrasonic signals between two sensors (A and B).

The transit time in flow direction t is shorter than it is against the flow direction t 2.

The difference between both transit times is proportional to the average flow velocity along the measurement path vM .The system calculates the average crosssectional area velocity vA from the path velocity vM and indicates it directly on the display.

Flow in full pipes is calculated by using the general equation of continuity:

Q= A • vA

A= cross-sectional area

v = average flow velocity in cross-sectional area

The Nivu Flow 600 Transmitter

The intuitive one-hand operation and the bright high-resolution colour display allow quick, easy and cost-efficient commissioning on site. Additional input devices or software are not required.

On site from anywhere

- Integrated data logger for high data security

- Saved data can be recalled at any time

- Online operation and online setting of parameters (remote control)

- Quick and comprehensive remote diagnostics of entire measurement place

| Technical Information |

| Power consumption |

1 relay energised, 230 V AC: (rounded) 14 W |

| Weight |

approx. 1150 g |

| Storage temperature |

−30 °C to +80 °C |

| Max. humidity |

80 %, non-condensing |

| Display |

240 x 320 Pixel, 65536 colours |

| Operation |

rotary pushbutton, 2 function keys, menus in English, German, French, and others |

| Connection |

plug with spring cage terminal blocks |

| Inputs |

- 1x (Type T2) 4-20 mA, with 12 Bit resolution for storage of data from external units, load 91 Ohm,

- 1x (Type T2) digital input

|

| Outputs |

- 1x (Type T2) 0/4-20 mA, load 500 Ohm, 12 Bit resolution

- 1x (Type T2) bistable relay SPDT, load up to 230 V AC/2 A (cos j 0.9), minimum switching current 100 mA

|

| Data memory |

1.0 GB internal memory, readout on faceplate via USB stick |

| Communication |

- Modbus TCP via network (LAN/WAN, Internet)

- Modbus RTU via RS485 or RS232

- Ethernet TCP/IP

|

| Number of paths |

up to 4 |